2BEK Vacuum Pump

2BEK Vacuum Pump CN

2BEK Vacuum Pump Advantages:

1. Significant energy saving effect

The optimized hydraulic model design greatly improves the operating efficiency of the pump in the 160-1013hPa region, so it is more efficient and energy-saving.

2. Smooth operation and high reliability

Optimized hydraulic design, the impeller adopts a larger width-to-diameter ratio, so that the pump has higher efficiency than other series pumps when obtaining the same pumping volume. At the same time, the simple structure design makes the pump operation more stable and reliable, and the noise is lower.

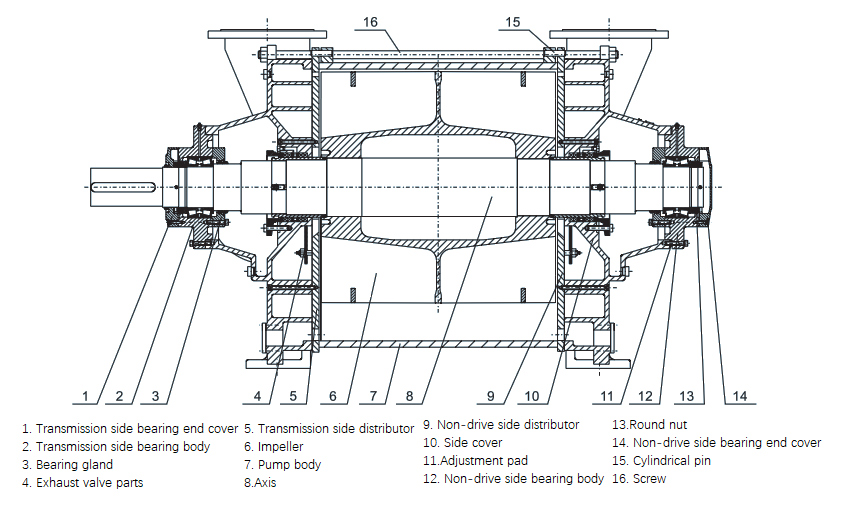

3. Outstanding structural advantages

Single-stage single-acting horizontal structure, simple and reliable, easy to maintain. The pump body structure with baffle can make one pump meet the requirements of two working conditions.

4. Strong adaptability

In order to meet different anti-corrosion requirements, the flow parts can be made of corresponding stainless steel materials. The flow parts are sprayed with a polymer anti-corrosion coating to meet the requirements of strong corrosion. The shaft seal has packing and mechanical seal options to meet the requirements of different working conditions

Related Key Words:

Vacuum Pump,Water Ring Type Vacuum Pump,etc