Submersible Axial,Mixed Flow Pump

ZQHQ Series Submersible Axial,Mixed Flow Pump

Submersible Axial,Mixed Flow Pump Advantages:

1. High adaptability

(1) Can transport clean water and lightly polluted water, with media temperature up to 40℃ and PH value of 4-10; The maximum diameter of passable particles is 100mm.

(2) Applications: urban water supply, diversion projects, urban sewage and drainage systems, sewage treatment works, power station drainage systems, water supply and drainage for docks, water network hub diversion, irrigation and drainage, aquaculture and so on. Submersible axial flow pump with high efficiency and good anti-cavitation performance, are suitable for occasions with large water level variations and high head, which is generally below 20m.

2. Less investment in pump station, and easy operation and management

(1) The pump works underwater, it requires much less earthwork and structural engineering in building pump stations as well as less installation area. As a result, the construction cost could be reduced by 30-40%

(2) Integration of motor and pump saves the time and labor-consuming on-site assembly procedure of 'motor – transmission mechanism – pump axis centering', thus bringing easy and fast on-site installation.

(3) Easy management, and low cost of management and operating .

(4) It’s easy to operate with remote and automatic control.

(5) Low noise, without high-temperature area in pump stations; ensure operating environment well; fully underground pump stations could be built according to requirements, so as to retain environmental style and feature on the ground.

(6) It's the best choice to solve flood prevention problems for motors installed in pump stations that are located along rivers and lakes with great water level fluctuations. In addition, by saving the long axis and intermediate bearings between motor and pump, the unit could run more stably and reliably.

3. High reliability, no vibration, and low noise

(1) With excellent hydraulic model, ensure users’ performance requirements. Interchangeability with traditional models for users to choose. There are a series of these pumps, which have awide high-efficiency range, applicability to different working conditions, high energy efficiency, and low operating costs.

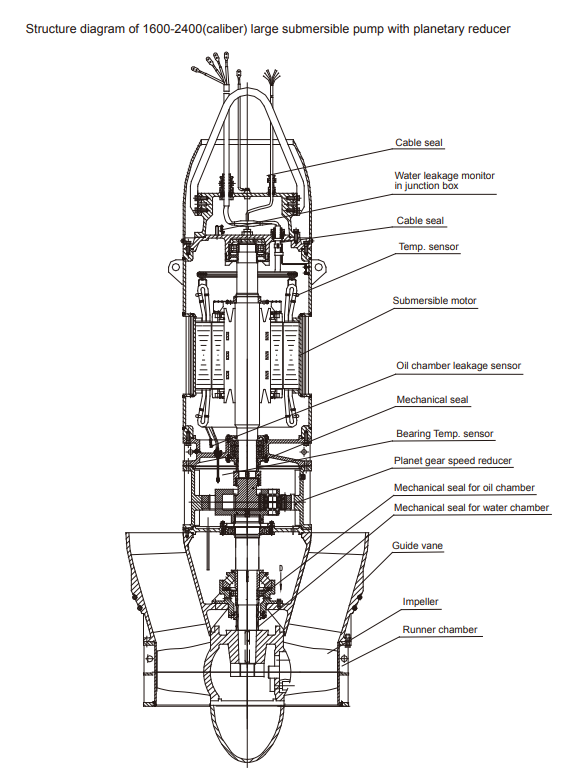

(2) The double or triple mechanical seals prevent leakage. Adequately lubricated special thrust bearings with reasonable structure design and long service life are adopted.

(3) With Grade F insulation, and come with temperature protection, monitoring, leakage sensor and other warning units.

(4) With good cooling conditions as submersible in water, Operating stable with minimal vibration, and low noise.

Related Key Words:

Submersible axial flow pump,submersible mixed flow pump, ,high flow submersible water pump.etc.

Submersible Axial,Mixed Flow Pump Structural Diagram

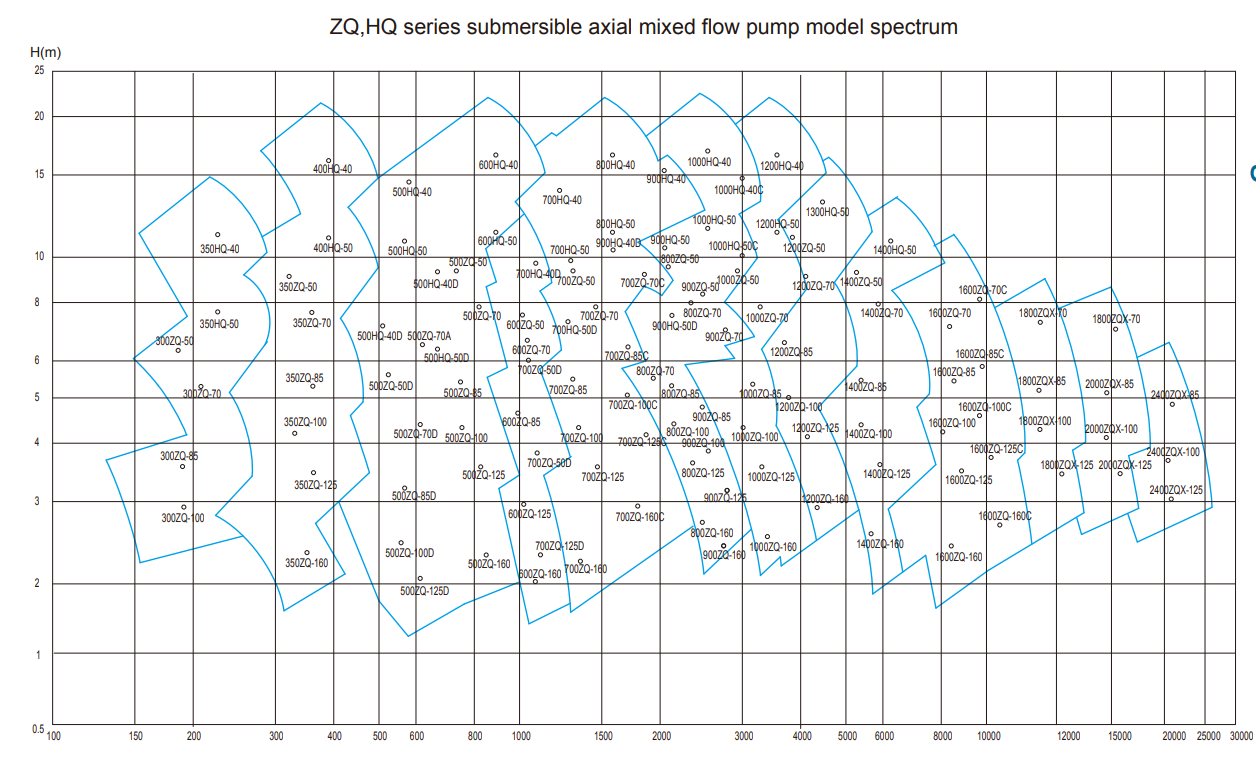

Submersible Axial,Mixed Flow Pump Spectrum Diagram and Description