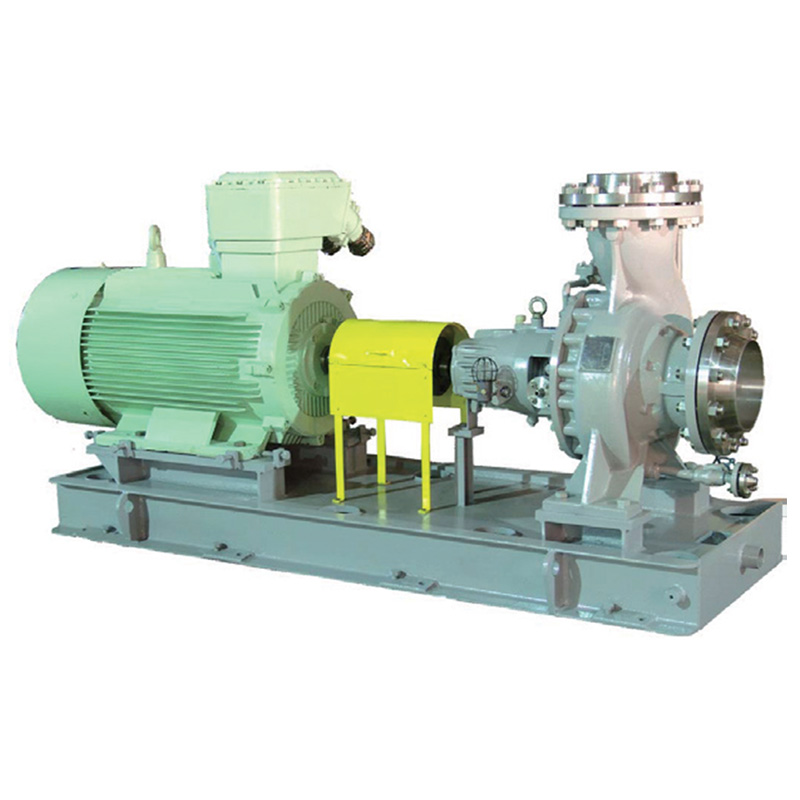

High Quality for Horizontal Chemical Pipeline Centrifugal Pump - KZ Series Petrochemical Process Pump Presentation – KAIQUAN

High Quality for Horizontal Chemical Pipeline Centrifugal Pump - KZ Series Petrochemical Process Pump Presentation – KAIQUAN Detail:

KZ Series Petrochemical Process Pump Presentation

API610 th8/th9/th10/th11 design standard.

capacity Q=0.5~3000m3/h

Head H=4~230m

Work pressure(p):maximum value can be 7.5MPa.

Work temperature(t): -45~+400

This series pumps are suitable to transfer clean or lightly polluted neutral or lightly corrosive liquid without solid particles. This series pump is mainly used to oil refining, petrochemical industry, chemical industry, coal processing, paper industry, sea industry, power industry, food, pharmacy, environment protection and so on.

1. KZA

KZA petrochemical centrifugal process pump is in accordance with AOI610 standard so there are some features below:

1) Pump structure is reliable and safe and pump operation is stable.

2) Pump efficiency on average is high with low energy conservation.

3) Pump cavitation performance is good and it is much better than the similar products. The minimum cavitation value can be 0.5m of many products, meanwhile, NPSHr value of general product is about 1m. Low NPSHr means low pump installation so that KZA pump means less construction cost.

4) Pump performance range is wide and maximum capacity can be 3000m3/h and maximum head can be 230m,meanwhile , pump capacity and head curves are closed so that it is convenient to select pump.

5) There are three bearing cooling forms, air cooling, fan cooling and water cooling according to different pump work temperature. The fan cooling especially is suitable for the areas lack of clean water.

6) Standardization and university is high. Beside the common standard components, the impeller and bearing body of KZA and KZE can be exchanged.

7) Pump wet parts material is selected from API standard according to work condition or customers.

8) Open impeller is also designed for this series pump for various work conditions.

Our company has received ISO9001 quality certificate.And there is a strict quality control system during pump design and process so that the quality can be guaranteed.

Parameters:

Performance range: Capacity Q=0.5~3000m3/h, Head H=4~230m

Work pressure(p): can be 2,5MPa(related to material and work temperature, shown as diagram P-T)

Work temperature(t): -45~+180

Standard speed(n): 2950r/min and 1475r/min

Application:

This series pumps are suitable to transfer clean or lightly polluted neutral or lightly corrosive liquid without solid particles. This series pump is mainly used to oil refining, petrochemical industry, chemical industry, coal processing, paper industry, sea industry, power industry, food, pharmacy, environment protection and so on.

2. KZE KZEF

KZE, KZEF Petrochemcial centrifugal process pump is manufatured in accordance with API610 so there are some features below:

1)Pump structure is reliable and safe and pump operation is stable.

2)Pump efficiency on average is high with low energy conservation.

3)Pump cavitation performance is good and it is much better than the similar products. The minimum cavitation value can be 0.5m of many products, meanwhile, NPSHr value of general product is about 1m. Low NPSHr means low pump installation so that KZA pump means less construction cost.

4)Pump performance range is wide and maximum capacity can be 3000m3/h and maximum head can be 230m, meanwhile , pump capacity and head curves are closed so that it is convenient to select pump.

5)There are three bearing cooling forms, air cooling, fan cooling and water cooling according to different pump work temperature. The fan cooling especially is suitable for the areas lack of clean water.

6)Standardization and university is high. Beside the common standard components, the impeller and bearing body of KZA and KZE can be exchanged.

7)Pump wet parts material is selected from API standard according to work condition or customers.

8)Open impeller is also designed for this series pump for various work conditions.

Our company has received ISO9001 quality certificate.And there is a strict quality control system during pump design and process so that the quality can be guaranteed.

Performance:

Performance range: Capacity Q=0.5~3000m3/h, Head H=4~230m

Work pressure(p): KZE 2,5MPa KZEF 7.5MPa(related to material and work temperature, shown as diagram P-T)

Work temperature(t): -45~+400

Standard speed(n): 2950r/min and 1475r/min

Application:

This series pumps are suitable to transfer clean or lightly polluted neutral or lightly corrosive liquid without solid particles. This series pump is mainly used to oil refining, petrochemical industry, chemical industry, coal processing, paper industry, sea industry, power industry, food, pharmacy, environment protection and so on.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for High Quality for Horizontal Chemical Pipeline Centrifugal Pump - KZ Series Petrochemical Process Pump Presentation – KAIQUAN , The product will supply to all over the world, such as: Tunisia, kazan, Jakarta, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.