Hot-selling Boiler Chemical Pumps - KDA Series Petrochemical Process Pump – KAIQUAN

Hot-selling Boiler Chemical Pumps - KDA Series Petrochemical Process Pump – KAIQUAN Detail:

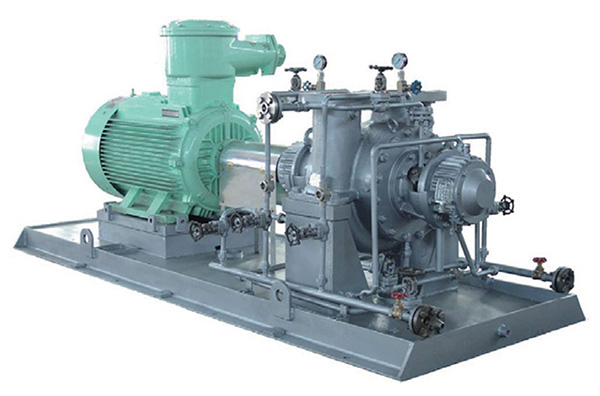

KDA Series Petrochemical Process Pump

KDA process pump is used for petroleum refining, petrochemical and chemical industry and other industry which needs to transport petroleum. The pump is completely accordance with API610 specifications.

KDA process pump has many advantages such as high reliability, long life and high universality. The efficiency is especially very high.

KDA pumps are single-stage double-suction centrifugal pumps with two ends support. The pump casing is radial spilt casing. It is especially suitable to transport high-temperature high-pressure flammable or toxic liquid. Its installation form is horizontal center line support to decrease the influence and displacement caused by the changed temperature. The pump body is designed as double volute to avoid the radial force.

The pump can exhaust automatically by flowing liquid with pressure. There is a hole reserved both on the pump volute and below the pump volute. If the customer wants the pump to exhaust or drain water, the hole can be drilled as an Rc3/4 threaded hole.

The pump suction flange and discharge flange, integrated with the pump body, are both straight up.The flanges designs are in accordance with ANSI standard. The maximum allowed pressure can be 5MPa.

For higher reliability, KDA process pumps casings are all cast steel casings which have passed the static test with 7MPa water pressure.

The seal chamber and the pump casing are integrated. It is suitable for packing seal, balance type mechanical seal or bellows pipe mechanical seal. There is an optional water cooling jacket outside the chamber. When the medium is water whose temperature is higher than 66, when the medium is hydrocarbon whose temperature is higher than 150 or the customer wants it, the water cooling jacket is needed. If necessary, steam with low pressure or other keeping warm material can be put into the cooling jacket to keep the pump medium’s temperature. The inlet cooling water joint Rc1/2 is below the pump cover and the outlet water joint Rc1/2 is on the pump cover. The inlet steam joint is on the cover while the outlet joint Rc1/2 is below the pump cover.

The impeller is inblock cast impeller. It passes the dynamic balance test together with the rotor.

The impeller and the shaft are drove together by a key. The rotor support form is two ends support.

The casing seal ring and impeller seal ring are both replaceable parts. The two impeller seal rings are different and the seal ring closed to the thrust bearing is smaller than the other one. So that it can cause a bit of axial force and the rotor will be pulled to one side, to avoid the rotor around move.

The two bearing bodies at the pump two ends have the same sides. Their materials can be cast steel or cast iron. And they are fastened on the bracket by bolts. The bearing closed to the coupling is a set of radial bearing. The bearings at other end are two sets of back-to-back thrust bearings. The bearings are lubricated by a oil slinger. There are some axial cooling fins used for air cooling (t<120) outside the bearing body. There are also two other cooling forms, air fan cooling (t=120—260)and water cooling(t>260). And the fan cooling is especially suitable for the area which is lack of clean water.

The fan can take the place of the anti-dust plate when it is fan cooling, which is the special feature of this pump. There is a water cooling jacket outside of the ball bearing body when it is water cooling.

There are equipped with a circle oil lever and a oil cup to monitor and control the oil level. There are also equipped with two copper anti-dust plates at two pump ends. The plates are useful to prevent the dust and water to get in the bearing. They can also avoid the oil leakage. And it can play a supporting role if the bearing is fracted.

KDA process pump is equipped with a flexible diaphragm extension coupling. So that it is convenient to disassemble the pump. And we can easily disassemble the impeller, bearing and shaft seal.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Hot-selling Boiler Chemical Pumps - KDA Series Petrochemical Process Pump – KAIQUAN , The product will supply to all over the world, such as: Puerto Rico, Barcelona, Gabon, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!