Special Design for Two Stage Centrifugal Fire Pump - YS Vacuum Water Diversion Device – KAIQUAN

Special Design for Two Stage Centrifugal Fire Pump - YS Vacuum Water Diversion Device – KAIQUAN Detail:

YS Vacuum Water Diversion Device

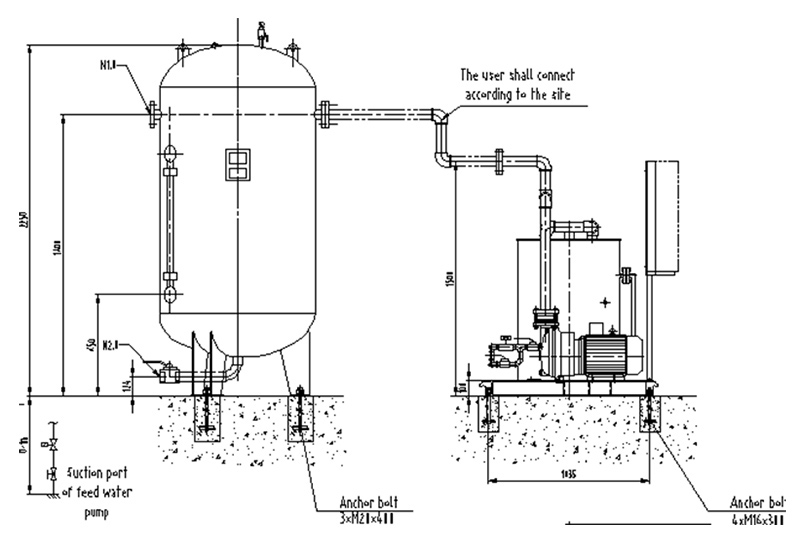

YS series type A automatic vacuum water diversion complete equipment, Model of control cabinet is KQK—YS110-2AN (N represents the number of water pumps).

1. The start and stop of the water pump is controlled by the water pump control cabinet; The solenoid valves inside the vacuum system and on the vacuum pipeline of the water pump are controlled by the vacuum system control cabinet. When the water pump is in standby state, the normally closed solenoid valve on the water diversion vacuum pipe needs to be in open state;When the water pump is in operation, the normally closed solenoid valve on the water diversion vacuum pipe needs to be closed. The start and stop of the vacuum pump is controlled by two level switch signals on the vacuum tank, high level shutdown and low level startup. The installation foundation of vacuum tank and pump can no longer be on the same plane, and attention shall be paid to that the low-level switch of vacuum tank is higher than the suction port of pump. At the bottom of the vacuum tank, there is a balance water pipe connected with the water inlet pipe of the water pump, and the valve of the balance water pipe is in a half open state.

2. During the initial water diversion, the two vacuum pumps work at the same time (manually pre water the vacuum pump before startup), and pump the water for evacuation. The solenoid valve on the vacuum pipeline of the water pump is opened – the vacuum pump is started – the solenoid valve of the working liquid water supply pipeline is opened at the same time – to start the water diversion. When the liquid level in the vacuum tank reaches high level, the pump cavity and suction pipe are filled with water to complete the water diversion. When the vacuum pump stops working, close the solenoid valve of the working fluid supply pipe of the vacuum pump and the feed water control cabinet of the feedback signal to start the pump, and the pump is in the standby state. When starting the water pump, the vacuum diversion control cabinet receives the command to close the solenoid valve of the corresponding diversion vacuum pipeline; similarly, when the water pump stops, the vacuum diversion control cabinet receives the command to open the solenoid valve on the corresponding diversion vacuum pipeline, and the water pump is in standby state.

3. As the solenoid valve on the vacuum pipeline of the water diversion is open when the water pump is in standby state, the leakage air of the pipeline, water pump and vacuum system will enter the vacuum tank, resulting in the decrease of the vacuum degree in the vacuum tank and the subsequent decrease of the liquid level. When the liquid level drops to the low level, the system will automatically start the vacuum pumping of the vacuum pump until the water level in the tank reaches the upper limit and then shut down. The ball valve of the connecting pipeline is always in the open state, and the liquid level in the vacuum tank changes with the pressure change. (during installation, ensure that the low-level switch position of the vacuum tank is higher than the water pump suction port, and gradually raise the balance water pipe and suction pipe towards the vacuum tank to avoid U-shaped pipe).

4. One of the two vacuum pumps is the main pump and the other is the standby pump, which works alternately. When the pump is evacuated again, the working pump works. If the required vacuum is not reached within the specified time, the working pump and the standby pump are started at the same time.

5. Start the standby vacuum pump and give an alarm to the central controller under the following conditions:

① The water level in the vacuum tank is lower than the low level and the main pump does not work;

② When the continuous operation time of the main pump exceeds the maximum setting value (such as 20 minutes), the standby pump starts and gives an alarm;

③ If the continuous operation time of the standby pump exceeds the maximum setting value (such as 20 minutes), an alarm will be sent to the water pump control cabinet.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Special Design for Two Stage Centrifugal Fire Pump - YS Vacuum Water Diversion Device – KAIQUAN , The product will supply to all over the world, such as: Honduras, Malaysia, Paraguay, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.